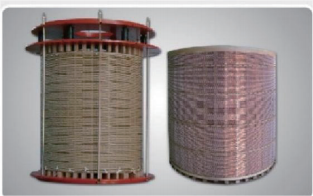

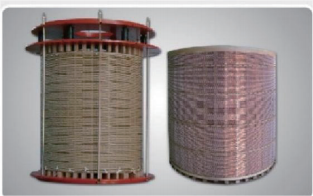

Product Introduction

Transposed Conductor is an important material for making transformer winding. it has the advantages ofhigh space utilization, low eddy current loss, high mechanical strength and less winding time. it is mainlyused to manufacture windings of power transformers, reactors and traction transformers.

Spenser specializes in producing copper and aluminum conductortransposition wires with accurate dimensions, short transposition pitchmoderate wrapping tightness, and continuous joint-free length of morethan 3500 meters.

Prodcution Type

Paperinsulated acetal enamelled transposing wire

Paperinsulated self-adhesive acetal enamelled transposing wire

Paper insulated self-adhesive semi-hard acetal enamelled transposing wire

Paperless binding acetalenamelled transposing wire

Step transposition composite conductor

Internalpaneltransposition combination conductor

Polyesterimide enamelled transposing wirePET

PET filminsulated acetal enamelled transposing wire

Users can specify the brand, model, and specification of insulationmaterials.

Technical Data

Transposed Roots:5-80EA(Odd or even both ok)

Max boundary dimension:120mm Height, 2mm Width, widthdeviation士0.05mm

Enamelled wire size:

Single conductorsize:thickness a:0.9-3.1mm deviation士0.1

b:2.50-13.00mm deviation士0.02mm

Optimal width vs thickness:2.0<b/a<9.0

Optimal thickness of Enamelled wire:0.08-0.12mm

Adhesive layer thickness:0.03-0.05mm

Pitch oftransposition:S=D·J/n

S-Pitch oftransposition

D- Coil minimum diameter

N- single enamelled wirequantity

Normally,the pitch of transposition is 8 to 12times of the single conductor width, up to 6 timesunder certain conditions,and the minimumtransposition pitch is 18mm.

Paper insulation wrapping method:

butt wrap---0.5 mm

0verlap wrapping with a gap of less than0.5 mm---2-4 mm

Overlap width 2-4 mm interlock wrap--Interleave 50%

boundary size calculation formula(odd roots):Transposition wireamplitude height

n--- Single enamelled wirequantity

W=2B+IW+?W

B--- Single enamelled wire width

w---Axialinsulationthickness (both sides)

w---Summation of axial dimensional tolerances(including interline gaps)

High quality oxygen-free copper rod selected toproduce the copper conductor,oxygen contentis less than 20 ppm, conductivity is greater than100% after annealing.

Optimal Non-proportional extension strength ofsemi-hard copper conductors (Rp0.2)如下as below:

C1 Rp0.2(>100~180)N/mm’Rp0.2<200N/mm,resistivity<1/58 Q.mm"/m

C2 R0.2>180~220)N/mm:Rp0.2<200N/mmresistivity<1/57.8Ω.mm'/m

C3 R0.2>220~260)N/mm2

High-quality electrician round aluminum rodwas used to produce the aluminum conductorconductivityis greater than 62% after annealing

Wrappinginsulation material

High quality of wrapping insulation material

Cable paper

High density insulation paper

Heat resist insulation paper

High elongation fiber paper

(Nomex)Aromatic polyamide Paper (Nomex)

PET film

Insulation material brand,type and speccustomized available. Material Standard

Material Standard

High quality oxygen free copper rods are selected for copper conductor processing, with an oxygen content of less than 20ppm. The conductivity of the conductor after annealing is greater than 100%

Optimal Pony Roll