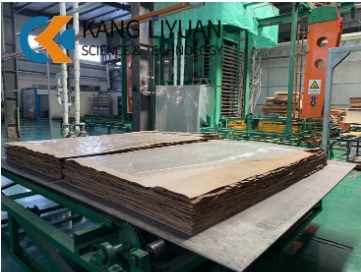

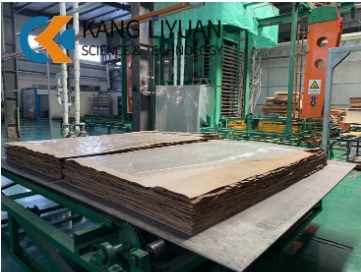

Electrical laminated wood is widely used as insulation and supporting material in transformers and instrument transformers. It has many merits such as high mechanical strength, high compatibility with transformer oil, etc. And it can be used in 105oC transformer oil for a long time.

People usually use this material to make pressure plates,spacer blocks in oil immersed transformers,as well as clamps in instrument transformers. It can replace steel plate, insulating paper sheets, epoxy paper sheets, epoxy paperboard woven glass fabric lamination in these fields. Thus, the weight of transformer and the cost of materials are reduced.

The raw materials of electrical laminated wood is the thin veneer of the birch, stained wood,northeast China ash and other high quality wood. The product is coated with special insulating glue and processed at high temperature and high pressure conditions.

Normal Thickness | Distance of any point on the upper surface of the veneer that deviates from the light weight straight ruler | ||

| Veneer length 500 | Veneer length 1000 | ||

| ≤15 | 2.0 | 4.0 | |

| >15…≤25 | 1.5 | 3.0 | |

| >25…≤60 | 1.0 | 2.0 | |

| >60 | 1.0 | 1.5 | |

Appearance Quality

| ltem | Allowed Range | |

| Swelling | Not Allowed | |

| Cracking | ||

| Dead Knot | ||

| Foreign-body Adhering | ||

| Insect Hole | ||

| Rot | ||

| Contamination | ||

| Bruising | ||

| Impression | A few allowed,not effect in usage | |

| Color-odds and Splash | ||

| Patches per sq.m. on surface | ≤3 | |