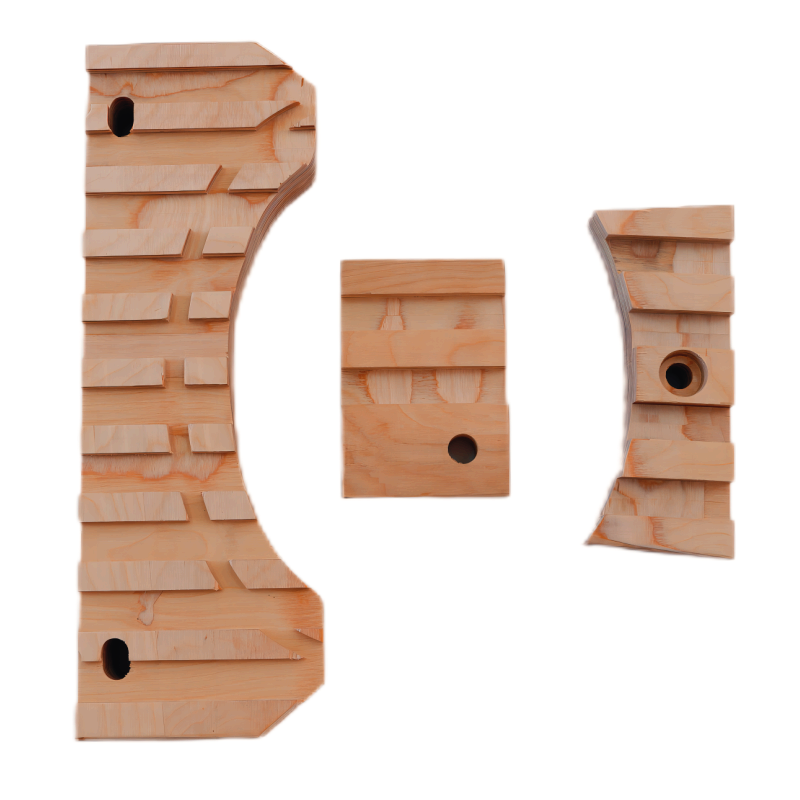

Laminated Wood/ Densified Wood/Plywood Sheet for Transformers

Top & Bottom pressure ring, Pressure Beams, core to coil packing, Lead & Cleat support, step block or core packing, Densified wood support, Fasteners & other items for Power & Distribution Transformers.