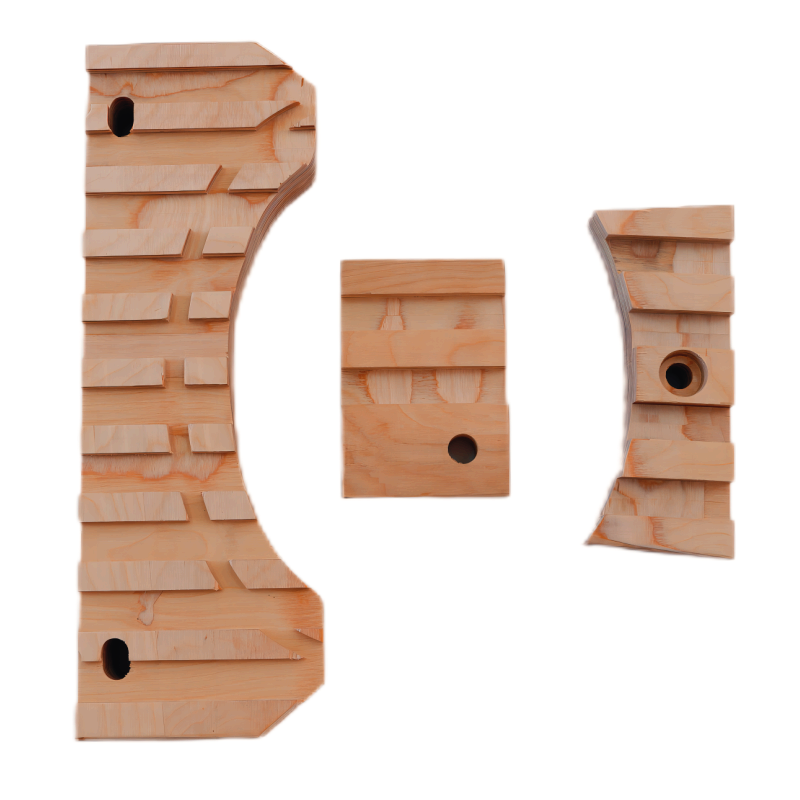

DescriptionPlywood is produced by gluing together, in high temperature (145-150oC) and under high pressure (6-12 MPa), beech veneers 2 mm thick bonded with special phenol-formaldehyde resin.Structure of transformer plywood can be crossed when the grain in neighbouring layers is at right angle and parallel with the grain laid parallel in each layer.

Features

FeaturesExcellent dielectric and mechanical properties.

Applicationsit is widely used for production of power transformers.

Appearance Quality

Manufacturing process

Manufacturing process

After being cut to size, each individual piece of veneer is impregnated with phenolic resin in a vacuum autoclave. Following impregnation, the pieces of veneer are baked in an oven to achieve a "B-stage" (partially cured) condition. The next step is to arrange and to stack the veneers to the desired configuration and thickness. Lamination, densification and complete curing are accomplished simultaneously in specially designed hot press machine. Standard sizes1500 x 1000 mm

1000 x 1500 mm

2000 x 1000 mm

3000 x 3000 mm

customized sizes and shapes are welcomed.