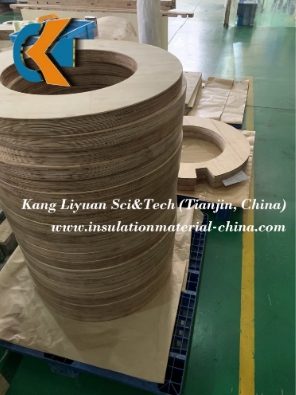

Laminated Wood for Thickness 25~60mm in Stock

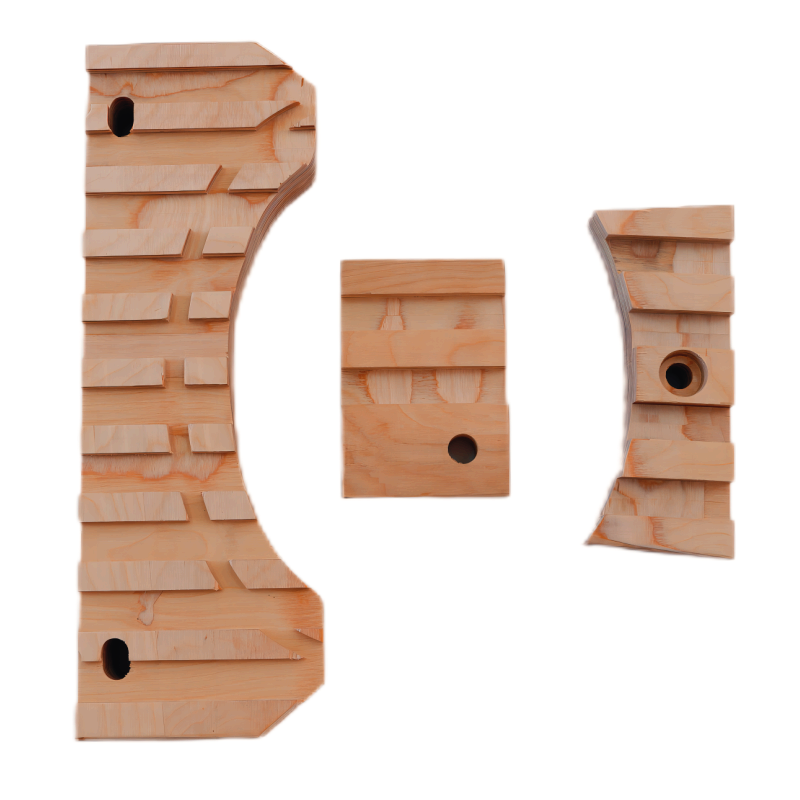

Structure of transformer plywood can be crossed when the grain in neighbouring layers is at right angle and parallel with the grain laid parallel in each layer.

The laminated wood raw matwrial is light in texture, and it is not easy to twist and crack. It has less gum and resin.

The raw materials of electrical laminated wood is the thin veneer of the birch, stained wood,northeastChina ash and other high quality wood.

The laminated wood raw matwrial is light in texture, and it is not easy to twist and crack.

It has many merits such as high mechanical strength, high compatibility with transformeroil, etc. And it can be used in 105C transformer oil for a long time.

Participate in the CWIEME Shanghai exhibition

Participate in the CWIEME Berlin exhibition

customer visit our stand

2022 CWIEME Berlin-Our Stand