DescriptionPlywood is produced by gluing together, in high temperature (145-150oC) and under high pressure (6-12 MPa), beech veneers 2 mm thick bonded with special phenol-formaldehyde resin.

Structure of transformer plywood can be crossed when the grain in neighbouring layers is at right angle and parallel with the grain laid parallel in each layer.

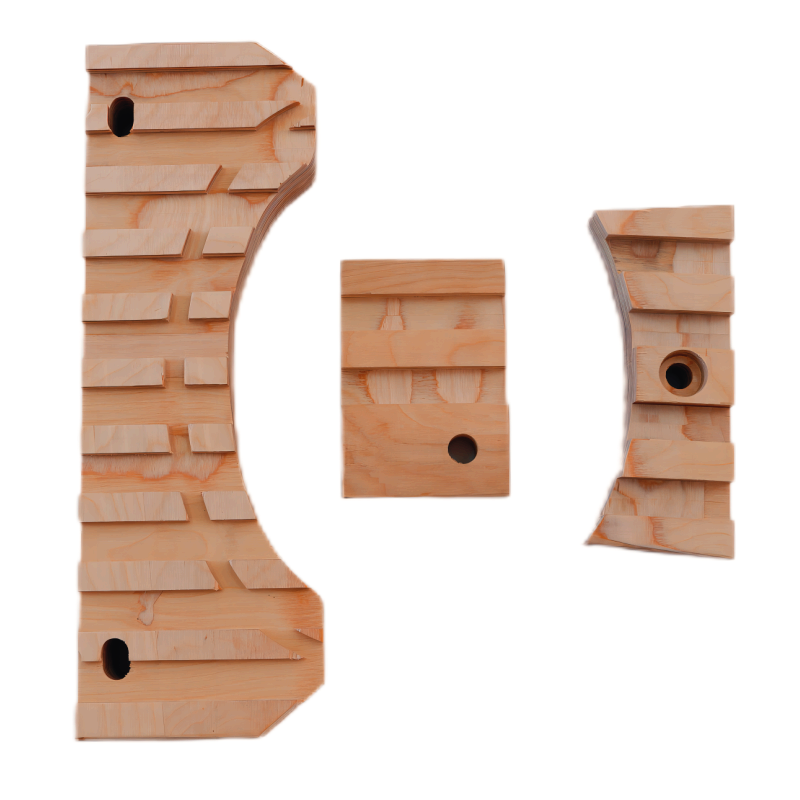

People usually use this material to make pressure plates,spacer blocks in oil immersed transformers,as wellas clamps in instrument transformers.It can replace steel plate,insulating paper sheets,epoxy paper sheets,epoxy paperboard woven glass fabric lamination in these fields.Thus,the weight of transformer and the cost ofmaterials are reduced.

The raw materials of electrical laminated wood is the thin veneer of the birch,stained wood,northeast China ash and other high quality wood.The product is coated with special insulating glue and processed at hightemperature and high pressure conditions.

FeaturesExcellent dielectric and mechanical properties

Apprearance Quality

Applications

Applicationsit is widely used for production of power transformers.

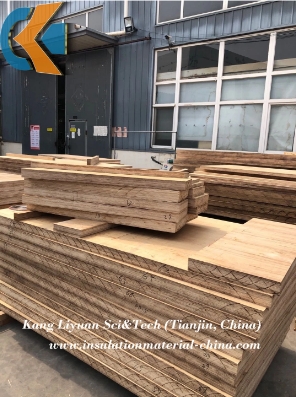

Available Standard sizes1500 x 1000 mm

1000 x 1500 mm

2000 x 1000 mm

customized sizes and shapes are welcomed.detailed picture: