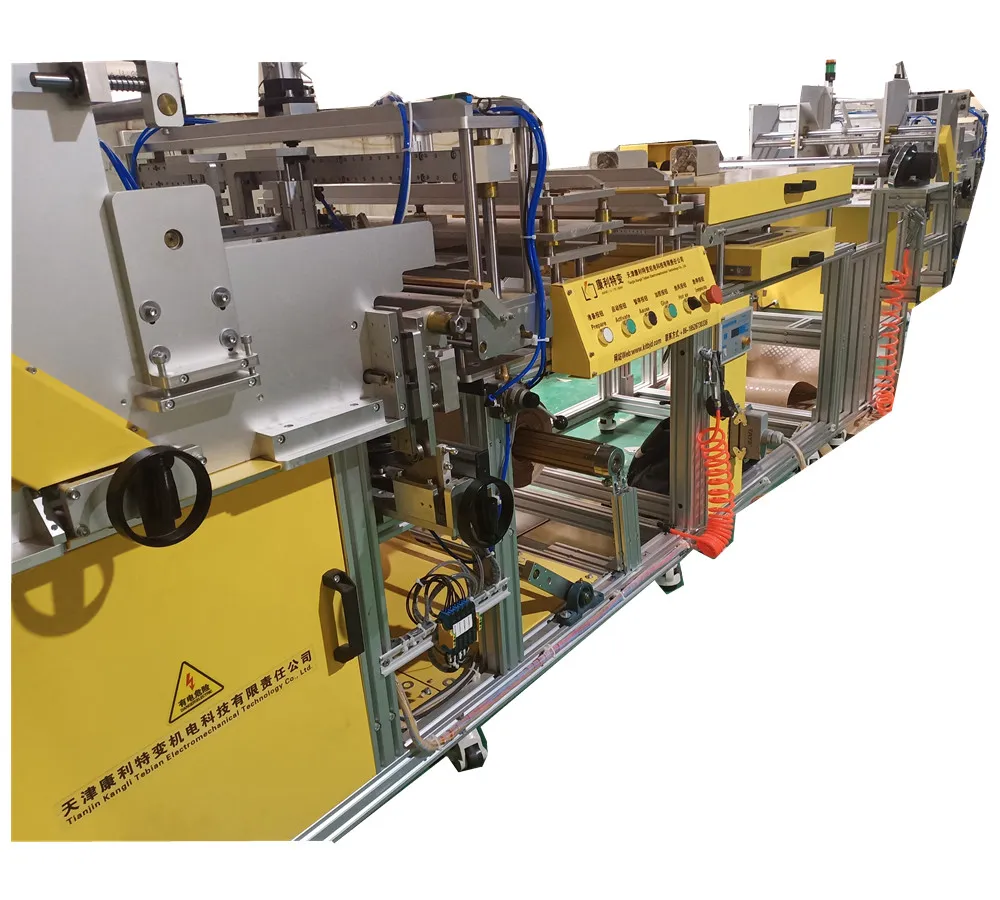

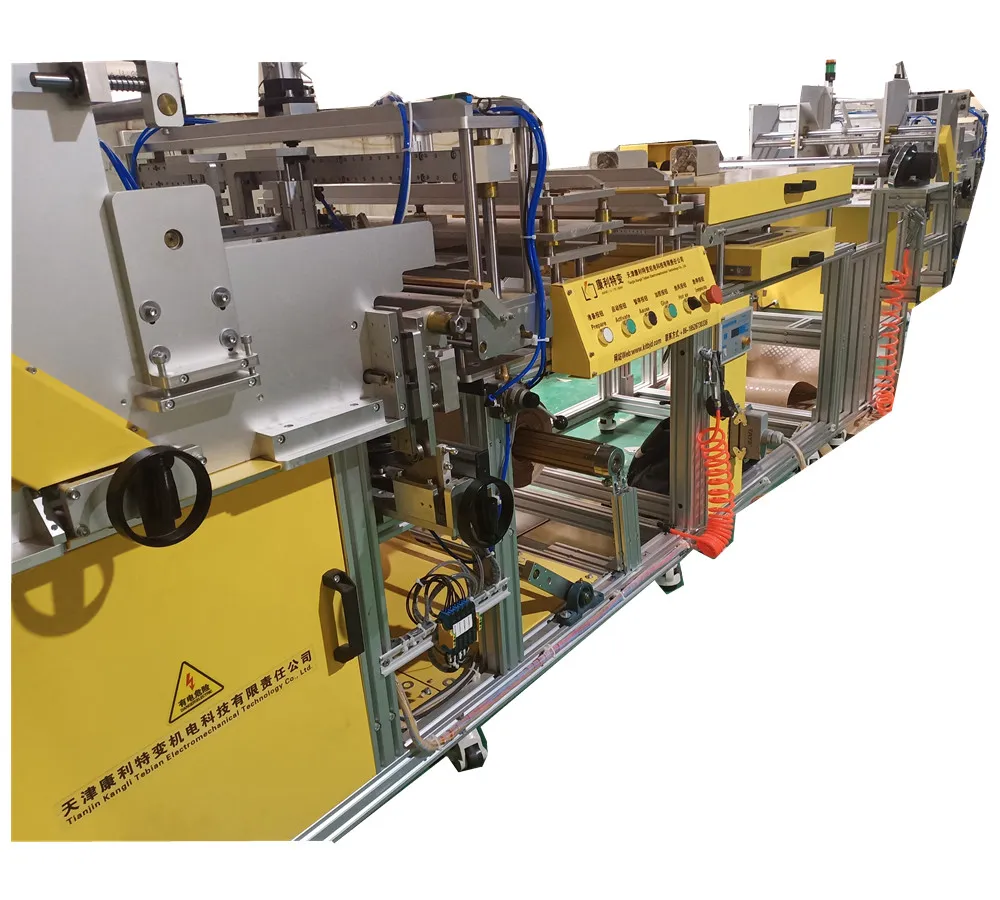

DescriptionThis is an intelligent machine capable of arranging, gluing and pressing the strips onto epoxy dotted paper/insulating paper. This machine is controlled by computer program and thus has high precision.Anode galvanized sheet surface,Siemens operation interface. Technical Parameters

Technical Parameters | No | Classification | Properties | A5 model |

| 1 | Operating properties | Strip feeding | Manually put, automatically straighten out the strip |

| 2 | Strip Length | 120-680mm |

| 3 | Strip Width | 5-12mm |

| 4 | Strip Thickness | 3-10mm |

| 5 | Paper thickness | 0.075-0.25mm |

| 6 | Bonding speed | 40/min |

| 7 | Spacing error(mm) | 0.02 |

| 8 | Glue | PVA / white latex |

| 9 | Compressed Air | 200 L/min,≥0.5mpa |

| 10 | Mechanical property | Device size | 2000-850-1650 |

| 11 | Device weight | 420 |

| 12 | Part surface | Anodized + white zinc |

| 13 | Electrical Property | Power | 5 kw |

| 14 | Voltage | 220Kv -single phase |

Technical details of individual component

Technical details of individual component 1.Public setting requirements for equipment use

1). Power supply requirements: single-phase 3-wire, 210-230vac,60HZ, incoming line capacity no less than 25A, and ground wire is well earthed.

2). Air source, air pressure no less than 0.5mpa, air supply flow not less than 500L/H.

2.Technical requirements for the bracing

Specification requirements for bracing (can be customized according to customer requirements)

1).Requirements for bracing:

A.It is a rectangle

B.The thickness range of the brace is 2.5-10mm, the width range is 5-10mm, and the length range is 120-620mm.

2) Requirements for bracing deformation: the bracing deformation includes longitudinal deformation (along the direction of thickness) and transverse deformation (along the direction of width). The longitudinal deformation will affect the feeding of bracing, while the transverse deformation will affect the mounting of bracing, so the deformation rate should be controlled at 1/500 to ensure the overall straightness of the brace.

3) Requirements for the processing: during the cutting, there will be size deviation and burr, etc. The tolerance of bracing is: the length ±1mm, width ±0.3mm, and the range of burr is less than 1mm3.

3.Equipment composition

1) discharging mechanism

2) push mechanism

3) gluing mechanism

4) mounting mechanism

5) pressing moving mechanism

6) auxiliary pressing mechanism

7) unwinding mechanism

8) winding mechanism

9) heating mechanism