Jul 01, 2020

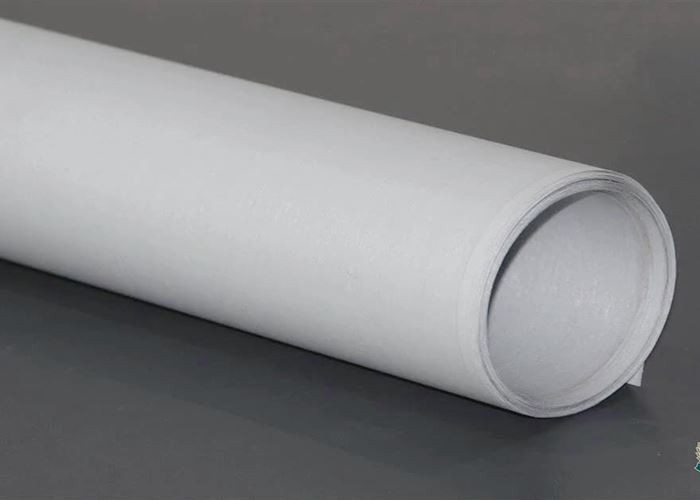

During use or storage of DMD insulated paper, its performance will irreversibly deteriorate over time. According to statistics, the failure rate of electrical equipment has a lot to do with the use time of insulating paper materials. There are many factors that contribute to its aging, mainly heat and electricity. In addition, there are several other factors that will also age the insulating paper material.

Insulation paper materials are subject to various mechanical stresses like constant or vibrating stress, and thermal expansion and contraction cycles, which can cause creep or fatigue damage.

Moisture of DMD insulation paper material will increase its conductivity and loss. Water also dissolves many substances, accelerating various chemical reactions that cause aging. Acid, or ozone can also cause chemical aging. For some insulating paper materials, water branching could occur at very low electric field strengths (see solid dielectric breakdown) due to the presence of moisture. In addition, in warm tropical regions, insulating paper materials will also be damaged by various microorganisms, which is so-called microbial aging.

DMD insulating paper materials ( when used outdoors) are often exposed to direct sunlight and will age under the action of ultraviolet rays. Insulation paper materials used in nuclear reactors and X-ray devices are subject to radiation, which will cause aging too.

Jul 31, 2020

Jul 30, 2020