Fully automatic control is realized by Siemens PLC control and touch screen. Only the relevant parameters (such as length, pitch, number of layers, dressing speed, wrinkle paper force) need inputting through the touch screen to realize fully automatic wrapping.

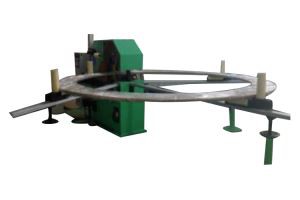

It is used for wrapping electrostatic rings in production of large-scale transformers and has distinctive advantages as follows: adjustable tensile force, wider diameter range of the workpiece, easy operation, and high efficiency, etc.

This is an intelligent machine capable of arranging, gluing and pressing the strips. This machine is controlled by computer program and thus has high precision.

This is an intelligent machine that can cut paper, put glue and roll the paper tubes. It has high production efficiency and can be operated individually.

Specification:

300 tons, 600 tons, 1500 tons, 2000 tons, 2500 tons, 3,000 tons

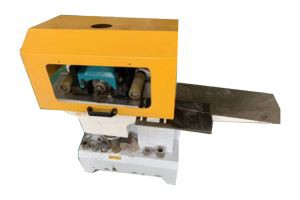

The device adopts fully automatic touch screen control. Workers input data on the screen, and the sheet that need processing can be cut with high precision.

This equipment is mainly used to process large insulation parts such as end rings, padding blocks and wire clamps in the transformer industry.

This is a smart machine that can automatically process multiple strips or round bars. It can process high-density electrical laminate wood and high-density paperboard within the diameter of 4-30mm.

CNC Wooden-step Block Milling Machine is used to process the wooden-step spacer used in transformers.

The paperboard beveling machine is mainly used to mill the bevelled joint of the insulating paperboard, to ensure consistent thickness when jointing.

The bonding machine is suitable for producing 10~35KVA distribution transformer coil end insulation parts.

It is designed specially for cutting the laminated insulating paperboard into strips.

Jul 31, 2020

Jul 30, 2020