May 20, 2020

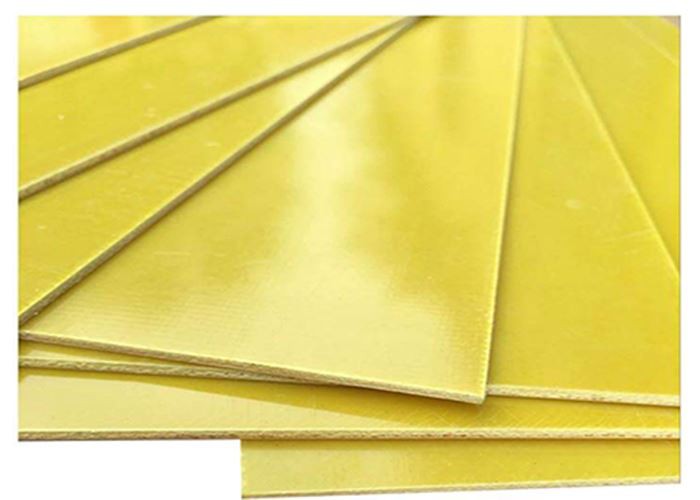

We all know that 3240 epoxy board has good insulation performance, high temperature resistance and good toughness. But what are the characteristics in processing epoxy boards?

(1) Good mechanical properties. That is, when it is subjected to various external loads (tensile, bending, impact, alternating) under different environments (temperature, medium, humidity), it can show good stability.

(2) Strong adaptability. Epoxy resins, curing agents, and modifiers can be adapted to various requirements on the form. It can range from very low viscosity to high melting point solids.

(3) Relatively wide curing temperature range. It can be cured within the range of 0-180 degrees.

(4) Low shrinkage. It is produced by direct addition reaction or ring-opening polymerization reaction of epoxy group in the resin molecule. No moisture or other volatile substances are released during processing. The shrinkage shown during the entire curing process is very low, generally less than 2%.

(5) Strong adhesion. Because the molecule contains polar hydroxyl and ether bonds, and the internal stress generated between the molecules is small, thus it has strong adhesion.

Jul 31, 2020

Jul 30, 2020