This machine adopts numerical control system, which is easy to operate. The press forming process can be complete simply by pressing the length and number of the spacers on the touch screen.

It adopts high-speed motor hydraulic structure, which is easy to operate and has high automation. Simply by placing the fixed width, length and number of swallow-tailed spacers under the horizontal arm

The paperboard round shear machine is mainly used for shearing transformer insulating paperboard and glass cloth board.

This machine is designed for manufacturing end rings for large-scale transformers. It is mainly used to mill the circular edges (inner and outer) as well as arc, straight and skew slots.

This machine is a special equipment for compacting and chamfering the strip paperboard.

This machine is designed specially for milling the laminated paperboard batten into R edge or chamfering angle for the spacers in the transformer oil gap.

It is designed specially for cutting the laminated insulating paperboard and the laminated electrical wood in a high speed .

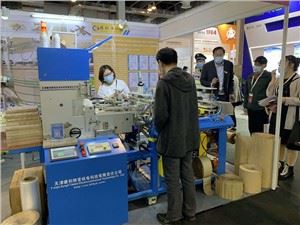

Mainly used in the manufacture of transformer oil duct and strips. Each time, It can produce 10 to 20 strips with smooth surface, which is five times efficiency of ordinary strips processing machine

The device is used for the rolling of the insulating paperboard, which is a key machine to shape the insulation paperboard cylinder.

After the transformer insulation board is milled and glued on the overlapping slope, the machine can then, through heat and pressure, bond the paperboard into a cylinder.

The amorphous layer insulation folding machine is mainly used for folding insulating paper between layers of transformer coils.

This is a special equipment for the assembly of amorphous alloy core transformer (amorphous transformer) body, which can be used to assembly both oil-immersed and dry-type transformer.

Jul 31, 2020

Jul 30, 2020